EQTEC as a company

EQTECs advanced gasification technology as we know it today came into being in 2011 with the commissioning of a 5.9 MWe facility at Mostos, Vinos y Alcoholes (Movialsa) S.A. in Ciudad Real, Spain. The facility, now in continuous operation for over a decade, cleanly converts the complex feedstocks of olive pomace and wine must into electricity and thermal energy used on site by the agro-industrial business, with any surplus electricity exported to the national grid. Annual audits of plant performance by an independent body indicate consistently high operational availability of 90%+ since 2015, when the audits commenced.

5.9 MWe

Electricity output per annum

6.6 MWth

Steam output capacity per annum

64%

Total plant efficiency

20,000 tonnes

Feedstock throughput per annum

120,000+

Independently audited operating hours

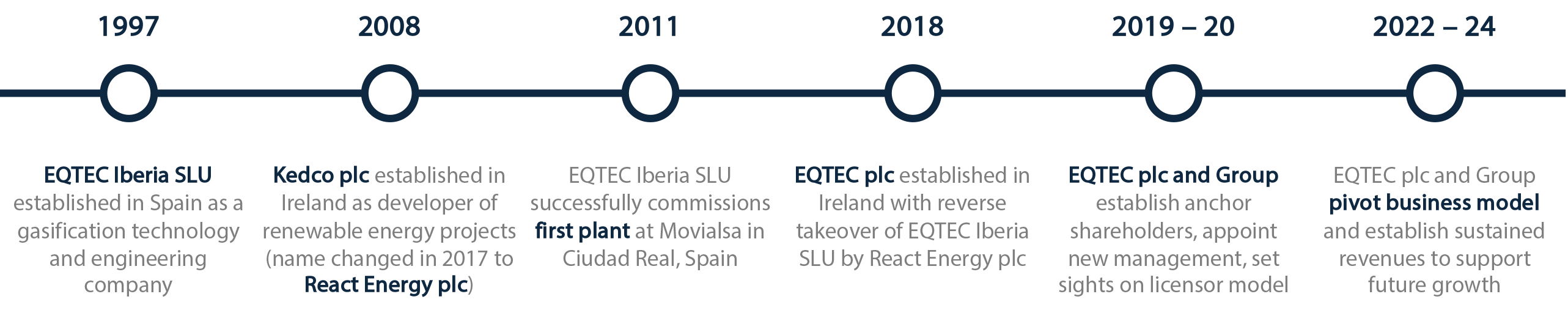

EQTEC plc and Group has evolved from the collaboration of chemical engineers and project developers to become a pure-play technology business focused on licensing and innovation.

EQTEC’s people have been innovating in gasification since 1997, with a range of patented and proprietary differentiators.

Cleantech innovation.

The Company’s chemical process engineers solved the notorious ‘tar problem’ well over a decade ago and nearly 20 years ago developed its kinetic model that recalculates complex reactions inside the gasifier every few microns, for a highly accurate sense-and-respond capability for modelling the gasification process during design, as well as for managing the gasification process throughout live operation of EQTEC-equipped plants.

Patented and proprietary.

The Company currently maintains four patents for its gasification process design and specific vessels deployed in that process. Further its, proprietary modelling and control systems are all programmed in house, ensuring that the process that EQTEC designs is the one that becomes live and operates consistently and effectively throughout the lifetime of its syngas plants. The Company anticipates pursuing several more patents in the near future, for more elements of its unique gasification capabilities and across multiple geographies.

Proven.

EQTEC has commissioned six plants since 2010, two of which are full, end to-end mini-plants for R&D, two of which were decommissioned and two of which are operational, commercial-scale plants. Two other plants are close to being commissioned and fully operational and several others are due to be operational within the coming years.

The following is a selection of EQTEC-enabled plants past, present and future:

| Lifecycle status | Commissioning | Plant | Location | Waste Feedstock | Capacity (Input) | Offtake Application | Capacity (Output) |

|---|---|---|---|---|---|---|---|

| Live | 2010 | U. of Extremadura | Spain | Biomass | 50 kg/hr | (R&D plant) | – |

| 2011 | Movialsa | Spain | Agricultural | 3 tonnes/hr | CHP | 5.9 MWe | |

| 2015 | U. of Lorraine (LERMAB) | France | Biomass, RDF | 100 kg/hr | (R&D plant) | – | |

| 2023 | EQTEC Italia MDC | Italy | Agricultural & forestry | 1+ tonne/hr | CHP, biochar | 1.0 MWe | |

| Completing commissioning | 2024 (est.) | Agrigas | Greece | Agricultural | 500 kg/hr | Electricity | 0.5 MWe |

| Completing construction | 2025 (est.) | North Fork | USA | Forestry | 3 tonnes/hr | CHP, biochar | 2.0 MWe |

| Under development | TBC | Grande-Combe | France | Mixed wood & RDF | 8 tonnes/hr | CHP | 6.5 MWe |

| TBC | Belišće | Croatia | Industrial | 2 tonnes/hr | CHP, biochar | 1.5 MWe | |

| TBC | Gardanne | France | Wood | 9 tonnes/hr | RNG | 3,000 Nm³ | |

| TBC | Limoges | France | Wood | 6 tonnes/hr | RNG | 2,500 Nm³ | |

| TBC | Colibri Plants (x4) | Italy | Mixed | 14 tonnes/hr | RNG | 8,000 Nm³ | |

| TBC | Simonpietri Enterprises | USA | Mixed | 3 tonnes/hr | CHP | 3.0 MWe | |

| TBC | Tresca Energía | Spain | Biomass TBC | 6 tonnes/hr | RNG | 2,500 Nm³ | |

| De-commissioned | 2015 | Karlovo | Bulgaria | Agricultural | 4 tonnes/hr | CHP | 5.0 MWe |

| 2016 | Belišće | Croatia | Agricultural | 1+ tonne/hr | CHP | 1.0 MWe |

Data above are provided at a point in time and are subject to change, according to project or client requirements.

EQTEC engineering

EQTEC’s engineers have worked on gasification since the 1990s.

EQTEC’s engineering team currently includes four PhDs in chemical engineering, with specialisms in gasification. CTO and inventor Dr Yoel S. Alemán Méndez started working professionally with gasification in 1997.

In 2005, Dr Alemán established highly accurate kinetic modelling to monitor complex reactions in the gasifier. By 2010, EQTEC had solved the ‘tar problem’ and in 2011 successfully commissioned its first installation at a plant in Spain.

At the heart of EQTEC’s capabilities are the specialist chemical, electrical, mechanical and instrumentation engineers that design, deploy and integrate EQTEC’s unique capabilities into client plants.

Dr Alemán’s mechanical and chemical engineering career includes nearly three decades’ experience with gasification as his chosen specialism. He has designed, built and operated thermochemical conversion facilities of various sizes and capacities for a wide range of feedstocks, including commercial–scale plants to handle biomass and non-biomass feedstocks (including RDF). He is the author of all of EQTEC’s patents and the lead inventor of its proprietary technologies. Yoel joined the Company in 2010, to rescue a project that was struggling at the Mostos, Vinos y Alcoholes, S.A. (Movialsa) agro-industrial facility in southern Spain. That initial, highly successful project, completed in 2011, established the platform for EQTEC’s proven technology capability. Dr Alemán has been an associated professor or researcher at three universities and earned a PhD in Chemical Engineering. Prior to his appointment to the EQTEC plc Board of Directors in 2019, he was Chief Technical Officer of EQTEC Iberia slu.

Dr Berrueco is a chemical engineer with over 20 years’ experience in the field of thermochemical processes and catalytic synthesis of biofuels. He holds a PhD in chemical engineering and has an outstanding scientific record, including scientific publications, participation in a good number of competitive and industrial research projects as well as several years as researcher at internationally recognized institutions, such as Imperial College London. César moved from research and academia to industry when he joined EQTEC in early 2018.

Dr Lorente is a chemical engineer with an extensive experience across nearly 20 years in research and development. As well as teaching activities at internationally renowned universities and research centres such as Imperial College London.Esther holds a PhD in chemical engineering and has participated in multidisciplinary projects, mainly focused on the development and optimisation of novel processes for energy generation and waste valorisation.

Denisa Rodríguez Royo

Project Manager

Sara Piqué Ferrer

Quality Manager

Oscar Velasco Hernan

O&M Manager

Ernesto Bravo Campos

Mechanical Engineer

Dr Javier Recari

Process Engineer

Liz de Abreu Devia

Process Engineer

Alex Martin

Process Engineer

Maria Belen Espiñeira

Process Engineer

Andrea Milagros Rodríguez Zambrano

Calculation & Design Technician

Marcos García Bartolomé

Automation Controls Engineer

Ariel Entenza Medina

Electrical Engineer

EQTEC leadership

EQTEC’s leadership team brings together veterans with decades of expertise and experience in business matters technical, operational, commercial and financial, and with track records in the private and public sectors with small-scale enterprises and major global organisations alike.

Board of Directors

Executive Leadership Team

Ian Pearson

Non-Executive Chairman

David Palumbo

Chief Executive Officer

Dr Yoel Alemán Méndez

Chief Technical Officer

Tom Quigley

Non-Executive Director

Brian Cole

Non-executive Director

David Palumbo

Chief Executive Officer

Dr Yoel Alemán Méndez

Chief Technical Officer

Murli Bhamidipati

Operations Director

EQTEC partner ecosystem

EQTEC’s uniquely capable syngas technology is at the core of new energy infrastructure projects that also solve for waste.

As the core technology provider and process engineering expert, EQTEC partners with others who operate across the value chain for infrastructure project development, delivery and plant operations.

Technology Partner

Wood is one of the world’s leading consulting and engineering companies operating across Energy and Materials markets, with 35,000 professionals across 60 countries and with annual revenues of c. $5.5 billion. Wood’s VESTA technology is an established solution for methanation or hydrogen separation from syngas, which is efficiently produced through EQTEC’s advanced gasification technology.

EQTEC and Wood have been acquainted since 2020 and in November 2021 signed a formal collaboration agreement aimed at joint development and sales of integrated technology solutions for converting a wide range of waste types into RNG (renewable natural gas) or hydrogen through EQTEC’s syngas technology and Wood’s VESTA technology.

Learn more ×

Utility Partner

Idex is a full-service owner-operator and energy provider that develops, designs, finances, builds and operates local energy and carbon-free infrastructures. Founded in France in 1963, now with over 6,300 employees and revenues of €2.3 billion in 2023, Idex is the only vertically integrated market operator delivering the complete value chain for local energy provision.

EQTEC and Idex are doing joint work on biomass and non-recyclable waste conversion into a range of solutions for sustainable, combined heat and power (CHP), renewable natural gas (RNG) and other offtake applications.

Learn more ×

Engineering Partner

CT3 Ingeniería S.L. has worked closely with EQTEC for over 10 years, leading the mechanical engineering work for most of the Company’s projects, past and present, including at North Fork in California, USA, Larissa in Thessalia, Greece, the EQTEC Italia MDC in Tuscany, Italy and all of EQTEC’s work in France.

With EQTEC leading the process engineering at the core of EQTEC’s solutions, CT3 provides world-class design, development and construction advisory services, including civil, mechanical and electrical engineering as well as Instrument & Control (I&C) and electrical services, across an increasing number of EQTEC-enabled plants.

Learn more ×

Technology Partner

The ERBE (Equipe de Recherche sur la Biomasse Energie) and LERMAB (Laboratoire d’Etudes et de Recherche sur le Matériau Bois) team is part of the LERMAB laboratory, a research centre at the Université de Lorraine. For the last 20 years, ERBE has worked on the thermochemical conversion of biomass and waste-to-energy.

For the past 10 years, the team has worked with EQTEC to co-develop a gasification pilot plant based on EQTEC’s bubbling fluidized bed Advanced Gasification Technology. Today, this partnership allows both parties to further test the gasification of biomass and waste for different uses, including cogeneration of electricity and gas (CHP), production of methane and production of hydrogen.

Learn more ×

Development Partner

Tresca Energía S.A., based in León, Spain, is an engineering, project development and project management company with the mission of supporting its clients in responding to industry challenges, by anticipating and managing change.

In recent years, Tresca has become one of the main actors in terms of projects associated with decarbonisation and new energy technologies on the Iberian Peninsula, based on its particular expertise with designing and developing plants that extract methane from syngas to produce biomethane or RNG or reform it into methanol.

This focus is especially relevant for EQTEC, whose advanced syngas technology produces an especially high-quality syngas that can maximise the methane component from a wide variety of feedstocks.

Learn more ×

Technology Partner

CompactGTL is one of the world’s leading, small scale, modular gas-to-liquid (GTL) companies. Since its inception in 2006, CompactGTL has focused its technology development and commercialisation programme on the upstream oil & gas sector but now sees a huge opportunity to transition the company toward a focus on biogenic feedstocks such as residual biomass, refuse derived fuels and municipal solid wastes that can be turned into valuable and sustainable liquid fuels.

EQTEC and CompactGTL established a collaboration framework agreement in 2022 and on the basis of business development and pilot work undertaken together under that agreement, announced in January 2024 a new, 50/50 joint venture (JV) now known as CompactWTL (for “waste-to-liquids”). The CompactWTL JV will pursue implementation of an integrated, waste-to-liquid fuel solution based on EQTEC syngas technology and CompactGTL gas-to-liquid conversion technology.

×

Development Partner

SenseESCO is a Croatia-based project development company founded in 2014 with financial and technical partners from Croatia, Germany and USA. With headquarters in Zagreb, the SenseESCO team researches, designs, finances, implements, operates and maintains energy efficiency, renewable energy and biomass waste-to-energy projects in Southeast Europe.

EQTEC and SenseESCO have worked together since 2015, identifying and qualifying opportunities in Croatia and elsewhere. The partners continue to pursue opportunities at Belišće and Karlovaç in Croatia, with at least two other prospective opportunities foreseen.

Learn more ×

EPC Partner

CosMi provides Engineering, Procurement and Construction (EPC) services and project management services for renewable energy plants. It employs professionals from the engineering sector with decades of developed experience in industries including steel, petrochemical and renewable energy.

EQTEC has worked with CosMi for nearly a decade on a wide range of projects where high-quality fabrication, installation and other construction and maintenance services are required. This includes collaboration at the EQTEC Italia MDC in Tuscany, Italy and all of EQTEC’s projects in France.

Learn more ×

EPC Partner

Petrofac is a leading energy services company whose purpose is to help its clients meet the world’s evolving energy needs by applying its engineering knowhow and consultancy expertise to design, build, and operate world-class energy facilities engineered for safety, optimal efficiency, and low emissions. Its New Energies business is focused on engaging a wide range of new technologies to support sustainable and renewable energy projects as the world transitions from energy derived from hydrocarbons.

EQTEC and Petrofac have been collaborating since 2020. Petrofac’s ability to operate in a range of markets and across the entire asset lifecycle, from design to decommissioning, makes it especially versatile as a partner.

Learn more ×

Project Management Partner

eCERTO is an innovative technology and advisory business with its origins in the oil and gas sector, committed to bringing decades of commercial insights with process technologies to renewables sectors. Its vision is to transform the sustainability and financial performance of capital projects across the energy sector with INTEGRATI®, eCERTO’s proprietary, Enterprise AI Platform for Capital Project Modelling.

EQTEC’s strategic partnership with eCERTO has led to increased interest from project funders approaching eCERTO to conduct independent due diligence in relation to investment opportunities in the renewable energy sector, leveraging eCERTO’s capital project modelling services powered by INTEGRATI®.

Learn more ×

Development Partner

Domi Ost is an Ireland-based project development company with the mission of sustainably decarbonising Ireland while ensuring business resilience. As Ireland seeks to decarbonise its energy grid and transport sectors by encouraging new, renewable technologies that support the country’s economic growth, Domi Ost is quickly finding routes to market for EQTEC’s syngas technology, as well as for other, complementary technologies.

EQTEC and Domi Ost together pursue sustainability opportunities for heavy energy user sectors and transport services in Ireland.

×

EPC Partner

IPM is a fully integrated engineering, procurement and construction management company that services a diverse set of industries with a focus on excellence in executing capital, maintenance and reliability projects. From front end feasibility studies to project completion, we strive to be your repeat service provider. It was founded in 2007 and is based in Texas, USA.

IPM and EQTEC have worked together on projects in California and IPM has also completed for EQTEC a comprehensive procurement review in the USA, toward US-based procurement of as much as 100% of EQTEC and ancillary equipment to support EQTEC installations in US projects. EQTEC anticipates future support from IPM on its projects there.

Learn more ×

Development Partner

Monte Cristo Engineering & Development was founded in 2006 to develop Beatrice Biodiesel, the largest most advanced biodiesel facility in the US at the time. Starting in 2008, MCED expanded to assist early stage technology companies and universities with process design, process scale-up, and development of demonstration facilities including fabrication and delivery of the of the systems. The focus of the work was primarily related to biofuels and bioenergy and supported customers globally.

Monte Cristo will develop US-based projects for EQTEC, starting with a specific opportunity in Hawaii.

Learn more ×