What makes EQTEC special

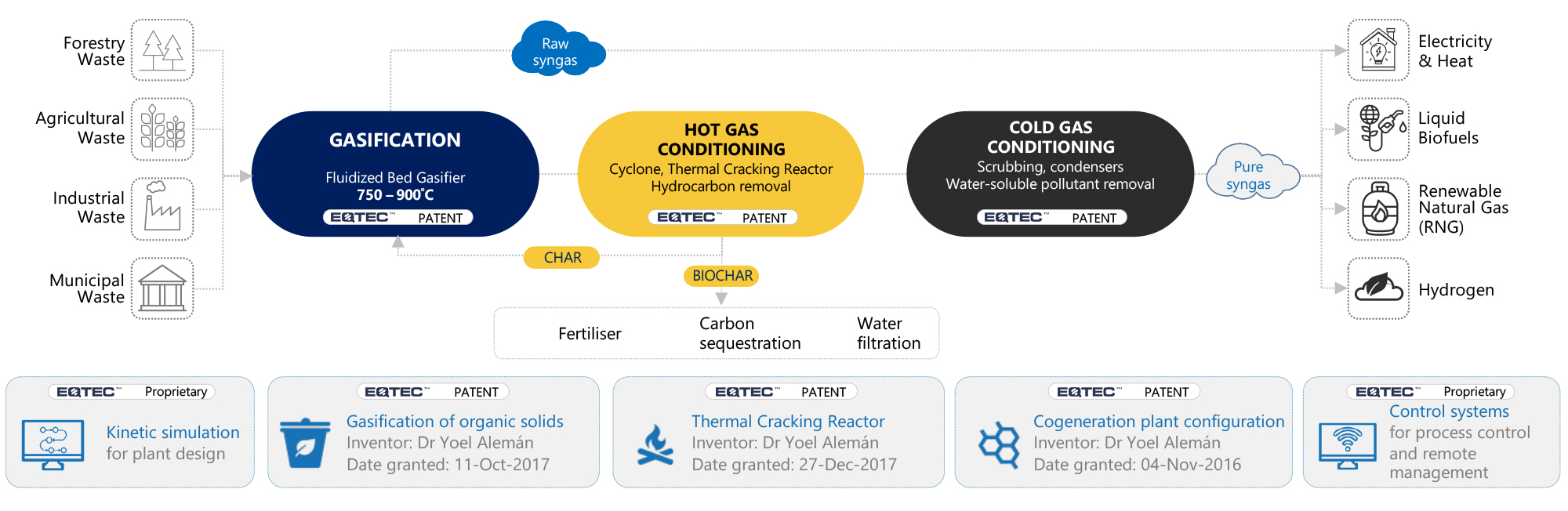

EQTEC is a leading licensor and innovator of syngas technology for clean conversion of the world’s waste into sustainable energy and biofuels.

What is syngas?

Syngas is shorthand for synthesis gas, a blend of hydrogen, methane, carbon dioxide, carbon monoxide and other elements in trace amounts, derived through the chemical conversion of carbonaceous materials. The quality and relative quantities of these component gases in syngas is heavily dependent on the efficiency of the chemical conversion process that produces them, as well as on the input feedstock used as raw material for the process. Syngas itself may be used directly as a fuel or process gas, or its component gases may be separated and applied as sources of energy.

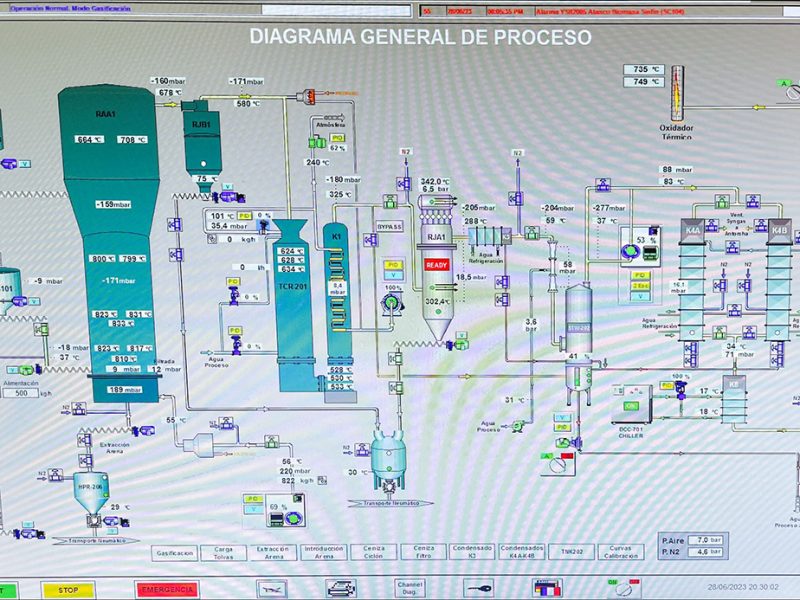

EQTEC technology

As one of the world’s most experienced thermochemical conversion technology and engineering companies, EQTEC designs, specifies and delivers solutions for clean energy from non-recyclable and other waste.

EQTEC R&D

EQTEC’s R&D programme is built on its long-standing relationship wiht the LERMAB facility at the Université de Lorraine in Épinal, France.

The ERBE (Équipe de Recherche sur la Biomasse Énergie) and LERMAB (Laboratoire d’Études et de Recherche sur le Matériau Bois) team and laboratory form a research centre at the Université de Lorraine built around EQTEC syngas technologies.

For the past 20 years, ERBE has worked on thermochemical conversion of biomass and waste-to-energy. For the past 10 years, the team has worked with EQTEC to co-develop a gasification pilot plant based on EQTEC’s bubbling fluidized bed Advanced Gasification Technology and especially, EQTEC’s air-blown gasification capabilities for producing syngas for traditional, combined heat and electric power (CHP).

At the end of 2022, a wide range of new opportunities for both EQTEC and LERMAB was made possible with upgrade of the facility for steam-oxygen gasification, which supports advanced syngas applications. Now, beyond testing a wide range of waste feedstocks for combined heat and power (CHP) applications, we are able to also test for syngas that can support methanation for renewable natural gas (RNG), hydrogen separation, Fisher-Tropsch (FT) gas-to-liquid process for sustainable aviation fuel (SAF) and other liquid fuels and even transformation into chemicals such as methanol or ethanol.

Because the EQTEC installation at LERMAB is an end-to-end industrial plant at small scale, rather than simply a test facility for part of the process, it is the ideal environment within which EQTEC can both test customer feedstocks and gasification processes as part of plant design and innovate its own technologies at speed.

Gasification:

Two types for different applications

Air-blown gasification supports electrical power and thermal energy applications, where the ratios of hydrogen, methane and carbon dioxide in the syngas is less critical for the offtake application. The LERMAB facility has had EQTEC air-blown gasification capabilities since its inception in 2015, and numerous trials are undertaken every year to validate and inform EQTEC’s and LERMAB’s capabilities and understanding.

Steam-oxygen gasification supports chemical applications such as hydrogen, renewable natural gas (RNG) and other advanced biofuel applications, where optimisation of the hydrogen, methane and carbon dioxide mix ratios is critical for efficiency and productivity of the offtake

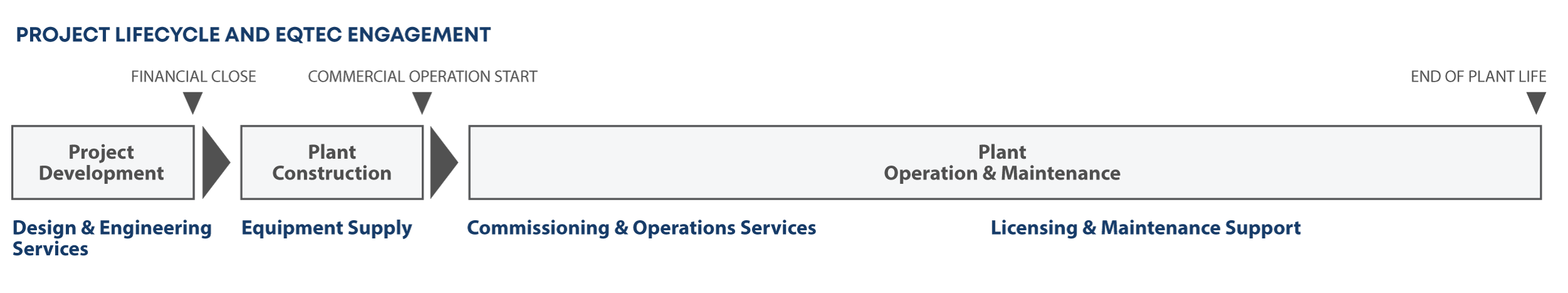

EQTEC business model

EQTEC is a technology company providing new energy infrastructure and waste management capability through innovative design, equipment and expert services.

EQTEC deploys its unique, world-leading syngas technology through services, equipment and licensing. The four key areas of customer delivery are outlined below:

Basic engineering (pre-FEED)

Front-end engineering design (FEED)

Estimations to support Financial Close/ FID

Final design & specification