Movialsa, Spain

Size

5.9 MWe & 6.6 MWt

Project Status

Commissioned

Category

Biomass-to-energy

Applications

Electricity, steam

Background

Project information

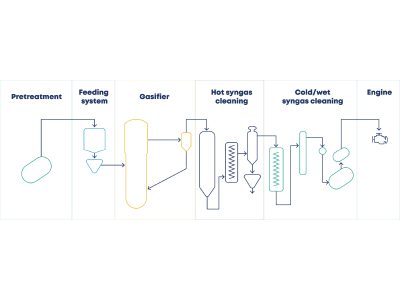

In 2011, EQTEC built a gasification plant at Movialsa in Ciudad Real, Spain, one of Europe’s largest producers of olive products and wine. Olive pomace waste is a difficult feedstock to process due to its high content of sodium and potassium as well as alkaline metals, all with very low melting points, and the challenge was in breaking down waste and putting it to good use. The second challenge was the need to make seasonal adjustments to the balance of electricity and heat production from the plant.

Over the years, we have developed and perfected our Advanced Gasification Technology at this plant, with audited data to demonstrate success for the client. As a result, we’ve been able to process olive pomace residue successfully, creating the first fully operational business case in the world for this feedstock, operating without subsidies or incentives.